Best Price for HD35 leaf spring - High quality china manufacturer T410012 Trailer leaf spring – Jiachuang Detail:

This spring assy are widely used in Thailand for trailer suspension parts .

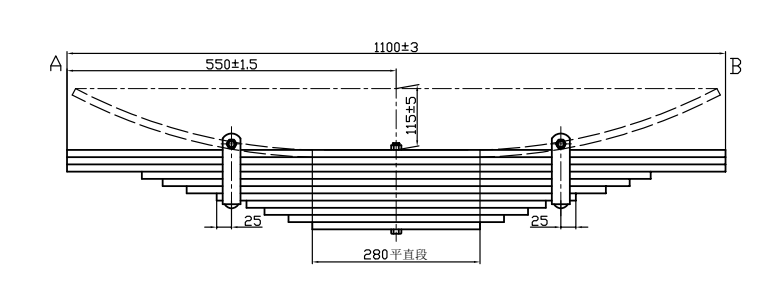

Spring Measurements Specs

Totally 11 blades ,1-11 blade Width(mm)*Thickness(mm): 100*12, End to End Measurement 1100 mm (Arc Length Measurement),Tolerance range within ±3mm . Camber Height Measurement (see picture) 115mm,Tolerance range within ±5 mm .

All datas are obtained by measuring the new produce product .

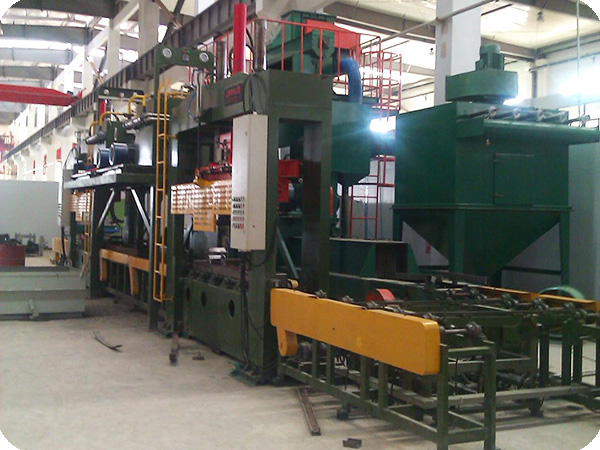

Trailer Leaf Spring Process

Multi-leaf springs are made as follows:

1.Shearing of flat bar

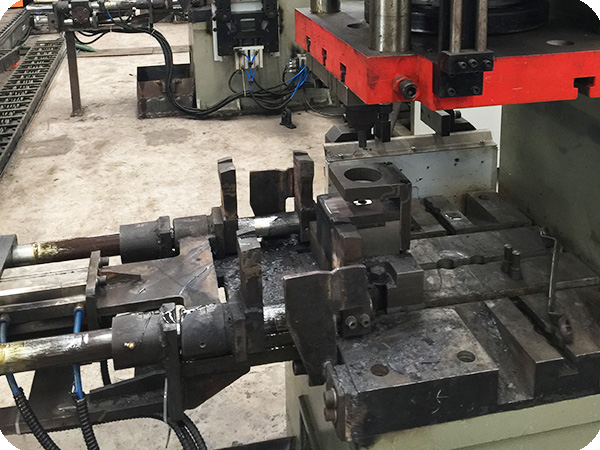

2.Center hole punching / Drilling

3.End Heating process

(1).Eye Forming / Wrapper Forming forming (hot & cold process)

(2).Diamond cutting / end trimming / width cutting / end tapering

(3).End punching / end grooving / end bending / end forging / eye grinding

(4).Center hole punching / Drilling / nibbing

4.Heat Treatment

(1).Heating

(2).Camber forming

(3).Quenching

(4).Tempering

5.Surface preparation

(1).Shot peening / stress peening

(2).Painting

6.Eye bush preparation process

(1).Eye reaming / eye boring

(2).Bush insertion

(3).Bush reaming

7.Assemble

(1).Presetting & load testing

(2).Paint touch-up

(3).Marking & packing

Finished Products and Pack Photos

Key Points Keep The High Quality

| 1) Raw matrail . |

| Thickness less than 20mm. we choose SUP9/55Cr3/SAE5160H as the product material |

| Thickness from 20-30mm. wE choose SUP11A/50CrVA |

| Thickness more than 30mm. We choose 51CrV4 as the raw material |

| Thickness more than 50mm. We choose 52CrMoV4 as the raw material |

| 2) Quchenging Process |

| We strickly controled the steel temeprure around 800 degree. |

| we swing the spring in the qenching oil among 10 seconds according to the spring thickness. |

| 3)Shot Peening. |

| Each assmembing spring set under stress peening . |

| Fatigue test can reach over 150000 cycus |

| 4) Painting |

| Each leaf under cataphoresis painting. |

| Salt spray testing reach 500hours |

Production Process

1.Material Cutting

4.Edge Cutting

7.Stress Peening

2.Punching

5.Quenching

8.Assembling

3.Eye Rolling

6.Tempering

9.Painting

FAQ

Q1: What type of leaf spring could you produce ?

A: We can produce most kinds of springs in the market. especially on the parabolic springs.

Q2: What material could you supply for leaf spring?

A: Our material grade should be SUP9/SUP9A /SUP11A/51CrV4 /52CrMoV4/ even 55Cr3 and SAE5160H as well .

Q3: How long will be your delivery time?

A: 20-40days. If material stock enough around 20days. if not,would be 40days

Q4: What payment terms are acceptable?

A: TT and LC at sight

Q5: What is the packing?

A: No fumigation wooden pallet . we also can pack according to whatever you request if reasonable.

Q6:How about the surface finishing ?

A : electrophoresis coating (black,red,gray,or as customer’s requests )

Product detail pictures:

Related Product Guide:

Dependable good quality and very good credit score standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of "quality initial, shopper supreme" for Best Price for HD35 leaf spring - High quality china manufacturer T410012 Trailer leaf spring – Jiachuang, The product will supply to all over the world, such as: Argentina, Korea, Armenia, The company has numbers of foreign trade platforms, which are Alibaba,Globalsources,Global Market,Made-in-china. "XinGuangYang" HID brand products sell very well in Europe, America, Middle East and other regions more than 30 countries.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!

-

China Gold Supplier for Shock Bushing Kit - To...

-

Personlized Products VOLVO FM9 Leaf Spring - H...

-

Leading Manufacturer for BPW Cranked Single tra...

-

Factory Price For Volvo Semi Truck Parts U Bolt...

-

Big discounting Sway Arm Bushing - Rubbber Fla...

-

Special Design for Actors 1831 Leaf Spring - H...