Europe style for Single Axle Trailer Leaf Springs - Professional manufacturer truck parabolic leaf spring for Nissan – Jiachuang Detail:

This spring assy are used for NISSAN truck .

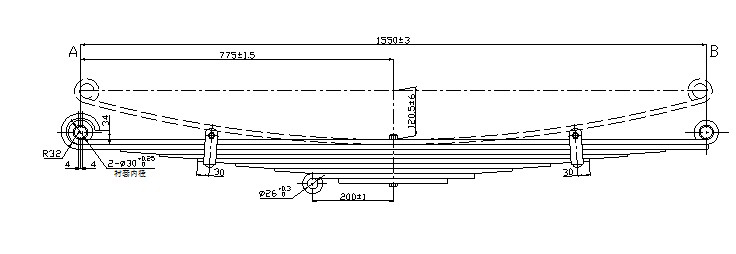

Spring Measurements Specs

Totally 9 blades , 1-9 blade Width(mm)*Thickness(mm): 90*12, Eye to Eye Measurement 1550 mm (Free Length Measurement),Tolerance range within ±3mm . 2pcs biametal bushesØ30*Ø36*88 comes to install spring eyes , 2-7 blade are taperred .

Free Arch Measurement (see picture) 120.5mm,Tolerance range within ±6 mm .

All datas are obtained by measuring the new produce product .

Parabolic Leaf Spring

Basically a parabolic spring is a spring that consists of two or more leaves. The leaves touch only in the center, where they are fixed to the axle and at the outer ends, where they are fixed to the vehicle. In between those two points the leaves do not touch each other as they do with conventional leaf springs.

Each leaf represents a complete spring in its self and will act as such. To enable the leaf spring is tapered, from the center (thick) to the outer ends (thin). This tapering is parabolic, it means that every centimeter (or inch) the thickness of the leaf decreases in an amount that relates to the square function of it’s length.

This may sound complicated but in fact it is very simple. Every single leaf will have, more or less, the shape of a complete multi leaf spring and thus it’s capable to cope with the same forces. This means that the ideal parabolic spring could have only one leaf, however, this type of “mono leaf” spring will have very limited articulation/weight ratio due to high internal stresses so a 2 or 3 leaf parabolic spring can divide the stresses more evenly across the other leaves and thus more axle movement is possible. That is why we designed 2 and 3 leaf springs. An other reason to increase the number of leaves on a parabolic spring is to increase the rate (load capacity). Because every leaf is one spring we can add or take out leaves without compromising the strength of the leaf it self. So for example we have a 3 leaf rear spring and we add one similar leaf the rate will go up for about 30% which means that the load capacity increases by +/- 30% (depending on the shackle effect)

Key Points Keep The High Quality

| 1) Raw matrail . |

| Thickness less than 20mm. we choose SUP9/55Cr3/SAE5160H as the product material |

| Thickness from 20-30mm. wE choose SUP11A/50CrVA |

| Thickness more than 30mm. We choose 51CrV4 as the raw material |

| Thickness more than 50mm. We choose 52CrMoV4 as the raw material |

| 2) Quchenging Process |

| We strickly controled the steel temeprure around 800 degree. |

| we swing the spring in the qenching oil among 10 seconds according to the spring thickness. |

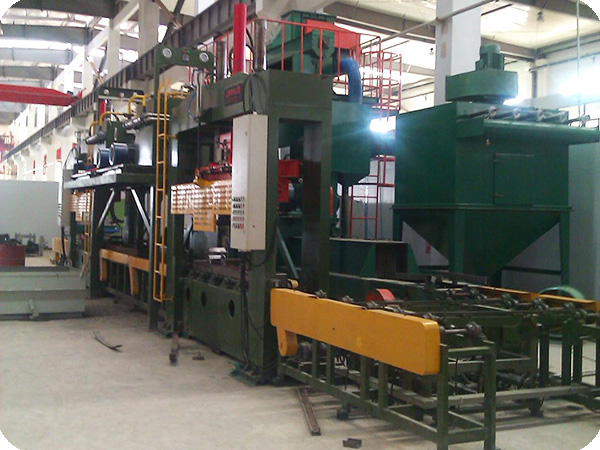

| 3)Shot Peening. |

| Each assmembing spring set under stress peening . |

| Fatigue test can reach over 150000 cycus |

| 4) Painting |

| Each leaf under cataphoresis painting. |

| Salt spray testing reach 500hours |

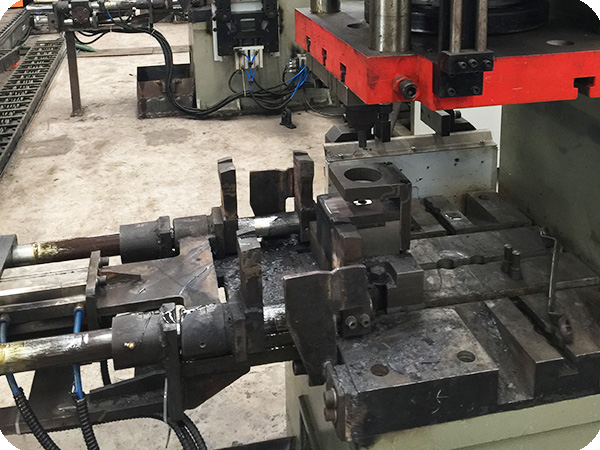

Production Process

1.Material Cutting

4.Edge Cutting

7.Stress Peening

2.Punching

5.Quenching

8.Assembling

3.Eye Rolling

6.Tempering

9.Painting

FAQ

Q1: What type of leaf spring could you produce ?

A: We can produce most kinds of springs in the market. especially on the parabolic springs.

Q2: What material could you supply for leaf spring?

A: Our material grade should be SUP9/SUP9A /SUP11A/51CrV4 /52CrMoV4/ even 55Cr3 and SAE5160H as well .

Q3: How long will be your delivery time?

A: 20-40days. If material stock enough around 20days. if not,would be 40days

Q4: What payment terms are acceptable?

A: TT and LC at sight

Q5: What is the packing?

A: No fumigation wooden pallet . we also can pack according to whatever you request if reasonable.

Q6:How about the surface finishing ?

A : electrophoresis coating (black,red,gray,or as customer’s requests )

Product detail pictures:

Related Product Guide:

We stick to our enterprise spirit of "Quality, Performance, Innovation and Integrity". We purpose to create a lot more price for our prospects with our rich resources, innovative machinery, experienced workers and great products and services for Europe style for Single Axle Trailer Leaf Springs - Professional manufacturer truck parabolic leaf spring for Nissan – Jiachuang, The product will supply to all over the world, such as: Lesotho, Ghana, Detroit, We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need to have!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!

-

professional factory for Leaf Spring Assy - Cu...

-

China Supplier Axle Pivot Bushing - AUDI Car P...

-

Reasonable price for Utility Trailer Leaf Sprin...

-

Factory wholesale Galvanised Square U Bolts - ...

-

Cheap price Stainless Steel U Bolt Clamps - Au...

-

Special Design for Trailer Leaf Spring Bushings...