Hot New Products Composite Leaf Spring - OEM 46-1189 Trailer suspension leaf spring for American market – Jiachuang Detail:

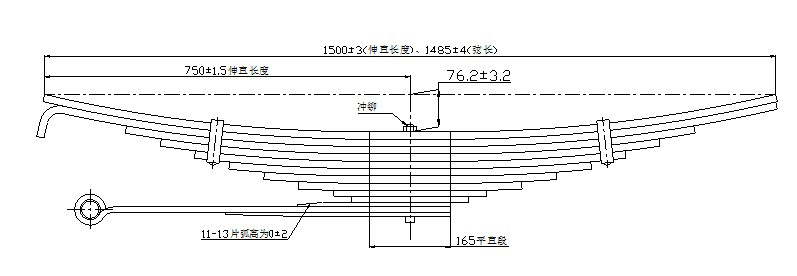

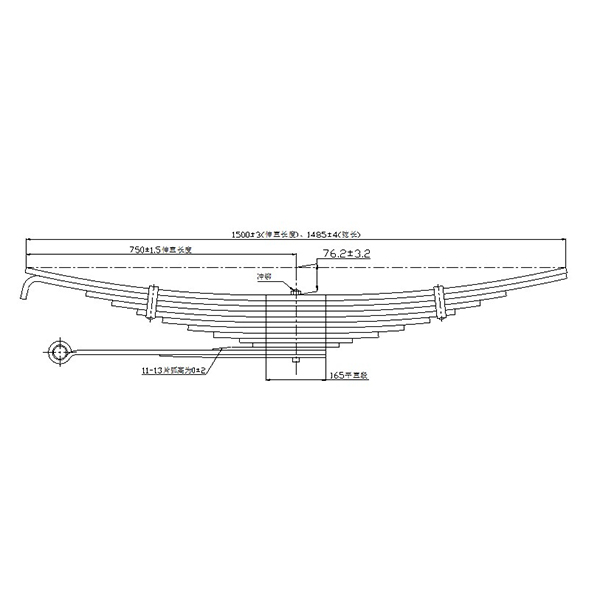

Spring Measurements Specs

Totally 13 blades ,1-8 blade Width(mm)*Thickness(mm): 76*15, 9-10 blade Width(mm)*Thickness(mm): 76*12 , 11th 13th blade 76*9 , 12th blade 76*11, end to end Measurement 1500 mm (Free Length Measurement),Tolerance range within ±3mm . 1pcs biametal bushesØ35*Ø41*74 comes to install spring eyes .

Free Arch Measurement (see picture) 76.2mm,Tolerance range within ±3.2 mm .

All datas are obtained by measuring the new produce product .

Freightliner Trucks Introduce

Freightliner Trucks is an American truck manufacturer ,it is known mainly for the heavy duty class 8 diesel trucks it also offers,classes 5-7 trucks and currently is part of daimler Trucks North America,LLC.

Class8 :FLA-Series(FLA,FLA-104,FLA-104-64,FLA-75,FLA-7542T,FLA-8662,FLA-8664T,FLA-9664,FLA-9664T),FLB,FLB-100-42T,FLB-104-64,FLB-9664)FLT-Series(FLT,FLT-6442,FLT-9664,FLT-7564),Argosy,FLC-Series(FLC.FLC-112/112-62-ST/120/120-64-T),108SD-AB,114SD-AB,114SD-AF,Class Series(Classic/XL),C-Series(Cascadia(ca125),Century(C120,Class S/T),Columbia(CL120),Coronado(CC132,SD),FLD-Series(FLD/112/120 42 S/120-64 ST/120-64 T/120-HD/120-SD/120-SFFA/132-64T-Classic-XL/SD)

Jiachuang Leaf Springs Advantage

01.No Rust problem + Perfect looking

Method:

>> Single leaf by electrophoretic painting(Optional)

>> Sembling spring by electrostatic painting(Optional)

Benefits for customers

>> Salt spray testing > 500 hours beat general industrial level 200 hours,avoid rust possiblity

>> Perfect-looking — uniform painting, complete painting, no scratch

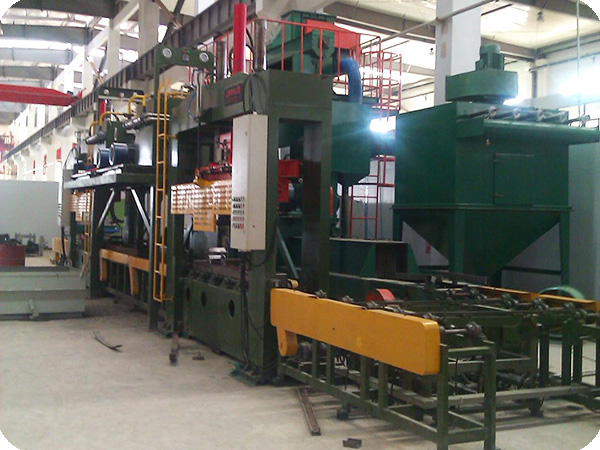

02. Pre shot-peening

Method:

>> Make shot peening under rated capacity

Benefits for customers

>> 180,000 times fatigue life beat general level 150,000 times;

>> bear heavier capacity and use longer time;

03. Pre-pressing and adjust

Method:

>> Make pre-pressing under rated capacity

>> Select camber by computer

Benefits for customers

>> Guarantee reasonable camber and keep smallest tolerance,

>> select out leaf spring whose camber is not qualified

Key Points Keep The High Quality

| 1) Raw matrail . |

| Thickness less than 20mm. we choose SUP9/55Cr3/SAE5160H as the product material |

| Thickness from 20-30mm. wE choose SUP11A/50CrVA |

| Thickness more than 30mm. We choose 51CrV4 as the raw material |

| Thickness more than 50mm. We choose 52CrMoV4 as the raw material |

| 2) Quchenging Process |

| We strickly controled the steel temeprure around 800 degree. |

| we swing the spring in the qenching oil among 10 seconds according to the spring thickness. |

| 3)Shot Peening. |

| Each assmembing spring set under stress peening . |

| Fatigue test can reach over 150000 cycus |

| 4) Painting |

| Each leaf under cataphoresis painting. |

| Salt spray testing reach 500hours |

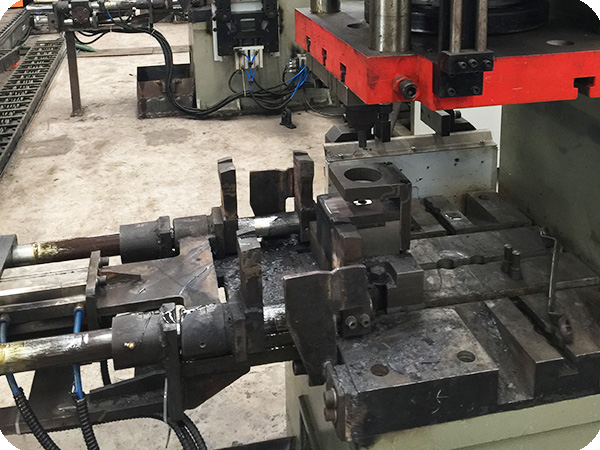

Production Process

1.Material Cutting

4.Edge Cutting

7.Stress Peening

2.Punching

5.Quenching

8.Assembling

3.Eye Rolling

6.Tempering

9.Painting

FAQ

Q1: What type of leaf spring could you produce ?

A: We can produce most kinds of springs in the market. especially on the parabolic springs.

Q2: What material could you supply for leaf spring?

A: Our material grade should be SUP9/SUP9A /SUP11A/51CrV4 /52CrMoV4/ even 55Cr3 and SAE5160H as well .

Q3: How long will be your delivery time?

A: 20-40days. If material stock enough around 20days. if not,would be 40days

Q4: What payment terms are acceptable?

A: TT and LC at sight

Q5: What is the packing?

A: No fumigation wooden pallet . we also can pack according to whatever you request if reasonable.

Q6:How about the surface finishing ?

A : electrophoresis coating (black,red,gray,or as customer’s requests )

Product detail pictures:

Related Product Guide:

Our solutions are widely regarded and trustworthy by consumers and may meet continually modifying financial and social requirements for Hot New Products Composite Leaf Spring - OEM 46-1189 Trailer suspension leaf spring for American market – Jiachuang, The product will supply to all over the world, such as: Paraguay, United Arab Emirates, United Arab Emirates, Our company has already had a lot of top factories and professional technology teams in China, offering the best products, techniques and services to worldwide customers. Honesty is our principle, professional operation is our work, service is our goal, and customers' satisfaction is our future!

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!