OEM China Nissan Leaf Spring - OEM 43-698 truck part front leaf spring with bushings – Jiachuang Detail:

This spring assy are widely used in American for heavy duty truck .

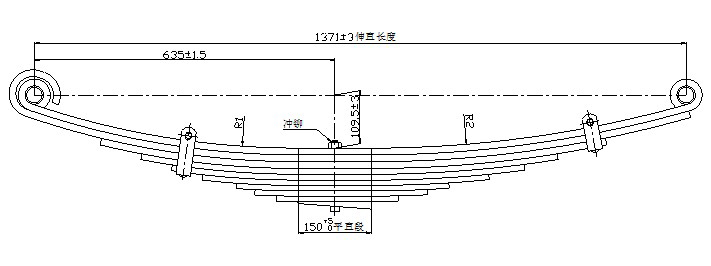

Spring Measurements Specs

Totally 9 blades , 1pc Inclined plate ,1-4 blade Width(mm)*Thickness(mm): 100*14, 5-6 blade Width(mm)*Thickness(mm): 100*13, 7-9 blade 100*11 , Eye to Eye Measurement 1371 mm (Free Length Measurement),Tolerance range within ±3mm . 2pcs biametal bushesØ32*Ø38*98 comes to install spring eyes .

Free Arch Measurement (see picture) 109.5mm,Tolerance range within ±3mm .

All datas are obtained by measuring the new produce product .

|

NO.Leaf |

W&T(mm) |

Length(mm) |

Per Weight(kg) |

Assy Weight(kg) |

|

1 |

100*14 |

635+736 |

18.44 |

82.2 |

|

2 |

100*14 |

635+736 |

17.41 |

|

|

3 |

100*14 |

486+562 |

11.89 |

|

|

4 |

100*14 |

400+460 |

9.45 |

|

|

5 |

100*13 |

336+390 |

7.86 |

|

|

6 |

100*13 |

273+317 |

6.02 |

|

|

7 |

100*11 |

203+235 |

3.78 |

|

|

8 |

100*11 |

165+190 |

3.07 |

|

|

9 |

100*11 |

120+130 |

2.16 |

Ford Trucks Introduce

The Ford F/L-Series are a series of full -size pickup and heavy duty trucks from the Ford Motor Company which has been sold continuously since 1948 till now for F-series and till 1988 for L-series .

Class 1: F-100,F-101,F-102,F-103,F-104,F-105,F-106,F-107,F-108,F-109,F-10N,F-110,F-111.

Class 2: F-112,F-113,F-140,F-141,F-142,F-143,F-150,F-151,F-250,F-250XLT,F-250HD,F250,F251,F252,F253,F254,F255,F256, F257,F258,F259,F260,F261,F262,F263,F264,F265,F266(Note:models produced in 1972-1979:F350,F351,F352,F353,F354,F355,F356,F357,F358,F359)

Class 3 : F-350,F-360

Class 4 : F-450

Class 5 : F-550

Class 6 : F-650

Class 7 : L-600/L-6000 series,L-700/L-7000 series

Class 7 : L-800/L-8000 series,L-900/L-9000 series

Key Points Keep The High Quality

| 1) Raw matrail . |

| Thickness less than 20mm. we choose SUP9/55Cr3/SAE5160H as the product material |

| Thickness from 20-30mm. wE choose SUP11A/50CrVA |

| Thickness more than 30mm. We choose 51CrV4 as the raw material |

| Thickness more than 50mm. We choose 52CrMoV4 as the raw material |

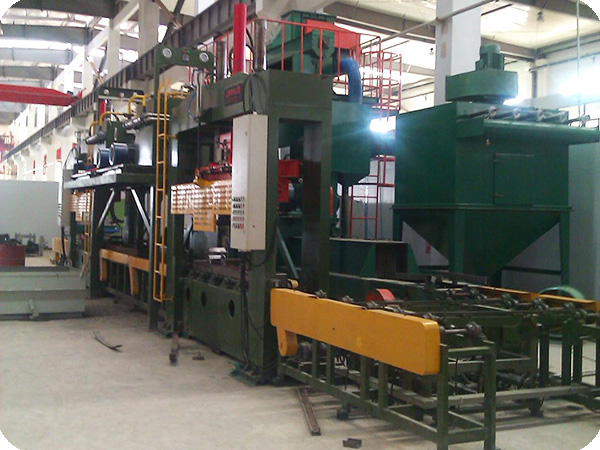

| 2) Quchenging Process |

| We strickly controled the steel temeprure around 800 degree. |

| we swing the spring in the qenching oil among 10 seconds according to the spring thickness. |

| 3)Shot Peening. |

| Each assmembing spring set under stress peening . |

| Fatigue test can reach over 150000 cycus |

| 4) Painting |

| Each leaf under cataphoresis painting. |

| Salt spray testing reach 500hours |

Production Process

1.Material Cutting

4.Edge Cutting

7.Stress Peening

2.Punching

5.Quenching

8.Assembling

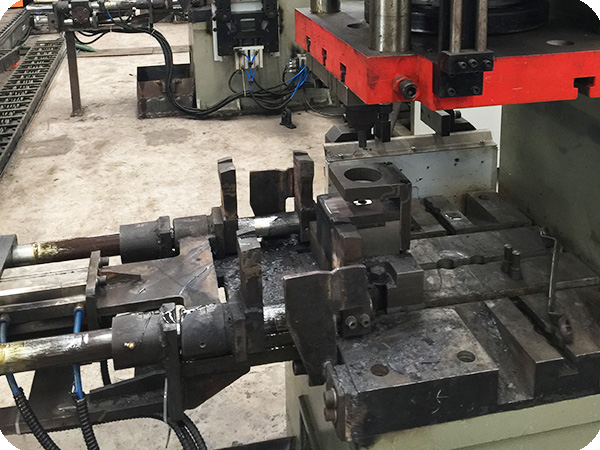

3.Eye Rolling

6.Tempering

9.Painting

FAQ

Q1: What type of leaf spring could you produce ?

A: We can produce most kinds of springs in the market. especially on the parabolic springs.

Q2: What material could you supply for leaf spring?

A: Our material grade should be SUP9/SUP9A /SUP11A/51CrV4 /52CrMoV4/ even 55Cr3 and SAE5160H as well .

Q3: How long will be your delivery time?

A: 20-40days. If material stock enough around 20days. if not,would be 40days

Q4: What payment terms are acceptable?

A: TT and LC at sight

Q5: What is the packing?

A: No fumigation wooden pallet . we also can pack according to whatever you request if reasonable.

Q6:How about the surface finishing ?

A : electrophoresis coating (black,red,gray,or as customer’s requests )

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for OEM China Nissan Leaf Spring - OEM 43-698 truck part front leaf spring with bushings – Jiachuang, The product will supply to all over the world, such as: Grenada, Moscow, Cologne, We have more than 200 staff including experienced managers, creative designers, sophisticated engineers and skilled workers. Through hard work of all employees for the past 20 years own company grew stronger and stronger. We always apply the "client first" principle. We also always fulfill all contracts to the point and therefore enjoy excellent reputation and trust among our customers. You are very welcome to personally visit our company.We hope to start a business partnership on the basis of mutual benefit and successful development . For more information please do no hesitate to contact us..

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.

-

Trending Products Round Bend U Bolts - Round h...

-

Wholesale Dealers of Front Bushes Car - Truck ...

-

Chinese wholesale Galvanized Trailer Leaf Sprin...

-

factory low price U Bolt Nuts - BPW truck part...

-

Wholesale Dealers of Hyundai Mighty leaf spring...

-

Top Suppliers Kamaz Leaf Spring - 24T Heavy du...