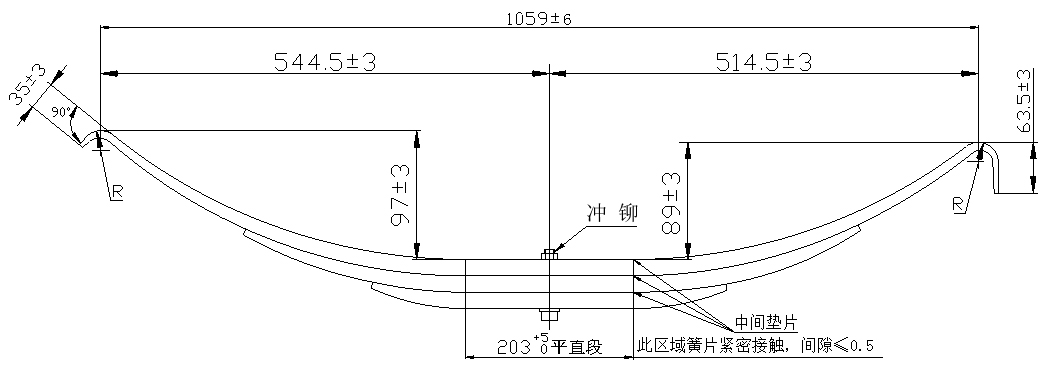

Special Price for Leaf Spring Rear Suspension - High quality china manufacturer SUP9 steel leaf spring for trailer 2728 – Jiachuang Detail:

This spring assy are widely used in American for trailer .

Spring Measurements Specs

Totally 3 blades , 3pcs middle pads , End to End Measurement 1124 mm (Free Length Measurement), A side Free Arch Measurement 97mm,Tolerance range ±3mm ,B side Free Arch Measurement 89mm,Tolerance range ±3mm, Middle straight 203mm .

All datas are obtained by measuring the new produce product .

|

NO.Leaf |

W&T(mm) |

Length(mm) |

Per Weight(kg) |

Assy Weight(kg) |

|

1 |

76*20 |

578+546 |

12.35 |

26 |

|

2 |

76*20 |

383+383 |

8.28 |

|

|

3 |

76*20 |

235+235 |

4.84 |

TRA2728 Leaf Spring Detail Photos

Key Points Keep The High Quality

| 1) Raw matrail . |

| Thickness less than 20mm. we choose SUP9/55Cr3/SAE5160H as the product material |

| Thickness from 20-30mm. wE choose SUP11A/50CrVA |

| Thickness more than 30mm. We choose 51CrV4 as the raw material |

| Thickness more than 50mm. We choose 52CrMoV4 as the raw material |

| 2) Quchenging Process |

| We strickly controled the steel temeprure around 800 degree. |

| we swing the spring in the qenching oil among 10 seconds according to the spring thickness. |

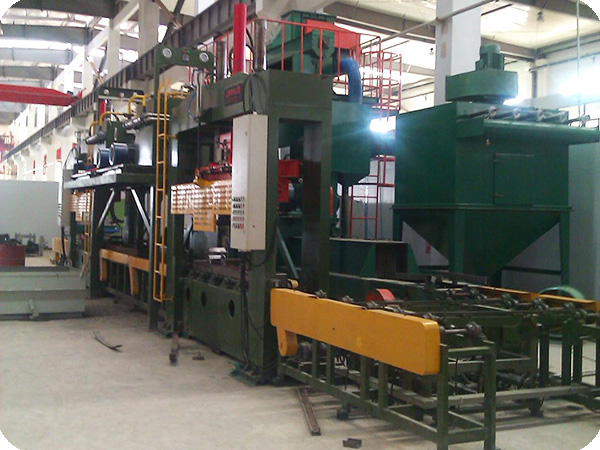

| 3)Shot Peening. |

| Each assmembing spring set under stress peening . |

| Fatigue test can reach over 150000 cycus |

| 4) Painting |

| Each leaf under cataphoresis painting. |

| Salt spray testing reach 500hours |

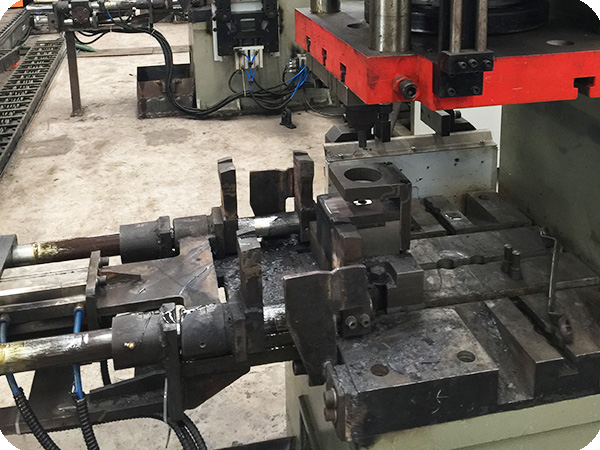

Production Process

1.Material Cutting

4.Edge Cutting

7.Stress Peening

2.Punching

5.Quenching

8.Assembling

3.Eye Rolling

6.Tempering

9.Painting

FAQ

Q1: What type of leaf spring could you produce ?

A: We can produce most kinds of springs in the market. especially on the parabolic springs.

Q2: What material could you supply for leaf spring?

A: Our material grade should be SUP9/SUP9A /SUP11A/51CrV4 /52CrMoV4/ even 55Cr3 and SAE5160H as well .

Q3: How long will be your delivery time?

A: 20-40days. If material stock enough around 20days. if not,would be 40days

Q4: What payment terms are acceptable?

A: TT and LC at sight

Q5: What is the packing?

A: No fumigation wooden pallet . we also can pack according to whatever you request if reasonable.

Q6:How about the surface finishing ?

A : electrophoresis coating (black,red,gray,or as customer’s requests )

Product detail pictures:

Related Product Guide:

We offer fantastic strength in high quality and enhancement,merchandising,income and marketing and procedure for Special Price for Leaf Spring Rear Suspension - High quality china manufacturer SUP9 steel leaf spring for trailer 2728 – Jiachuang, The product will supply to all over the world, such as: Singapore, The Swiss, Turin, We are seeking the chances to meet all the friends from both at home and abroad for the win-win cooperation. We sincerely hope to have long-term cooperation with all of you on the bases of mutual benefit and common development.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!

-

Fixed Competitive Price Custom Square U Bolts -...

-

Best Price on Travel Trailer Leaf Springs - Hi...

-

OEM Customized Hyundai Leaf Spring - High qual...

-

Manufacturer for U Nuts And Bolts - HINO truck...

-

Chinese wholesale Auto Parts - MAZDA Car parts...

-

Factory making Rubber Step Bushing - Durable S...