This spring assy are widely used in American for trailer .

Spring Measurements Specification

Totally 12 blades , 1-12 th blade Width(mm)*Thickness(mm): 100*12. Tolerance range ±3mm, A side Free Arch Measurement 73mm. Tolerance range +6mm , B side Free Arch Measurement 73mm, Tolerance range +6mm.

All datas are obtained by measuring the new produce product.

Axle Suspension Spare Parts T410012-12L Leaf Spring Characteristics

1. The T410012-12L LEAF SPRING acts as a linkage for holding the axle in position and thus separate linkages are not necessary. It makes the construction of the suspension simple and strong.

2. Because the positioning of the axle is carried out by the leaf springs, it is disadvantageous to use soft springs i.e. springs with low spring constant.

3. Therefore, this type of suspension does not provide good riding comfort. The inter-leaf friction between the leaf springs affects the riding comfort.

4. Acceleration and braking torque cause wind-up and vibration. Also wind-up causes rear-end squat and nose-diving.

5. The inter-leaf friction damps the spring's motion and reduces rebound, which until shock absorbers were widely adopted was a great advantage over helical springs.

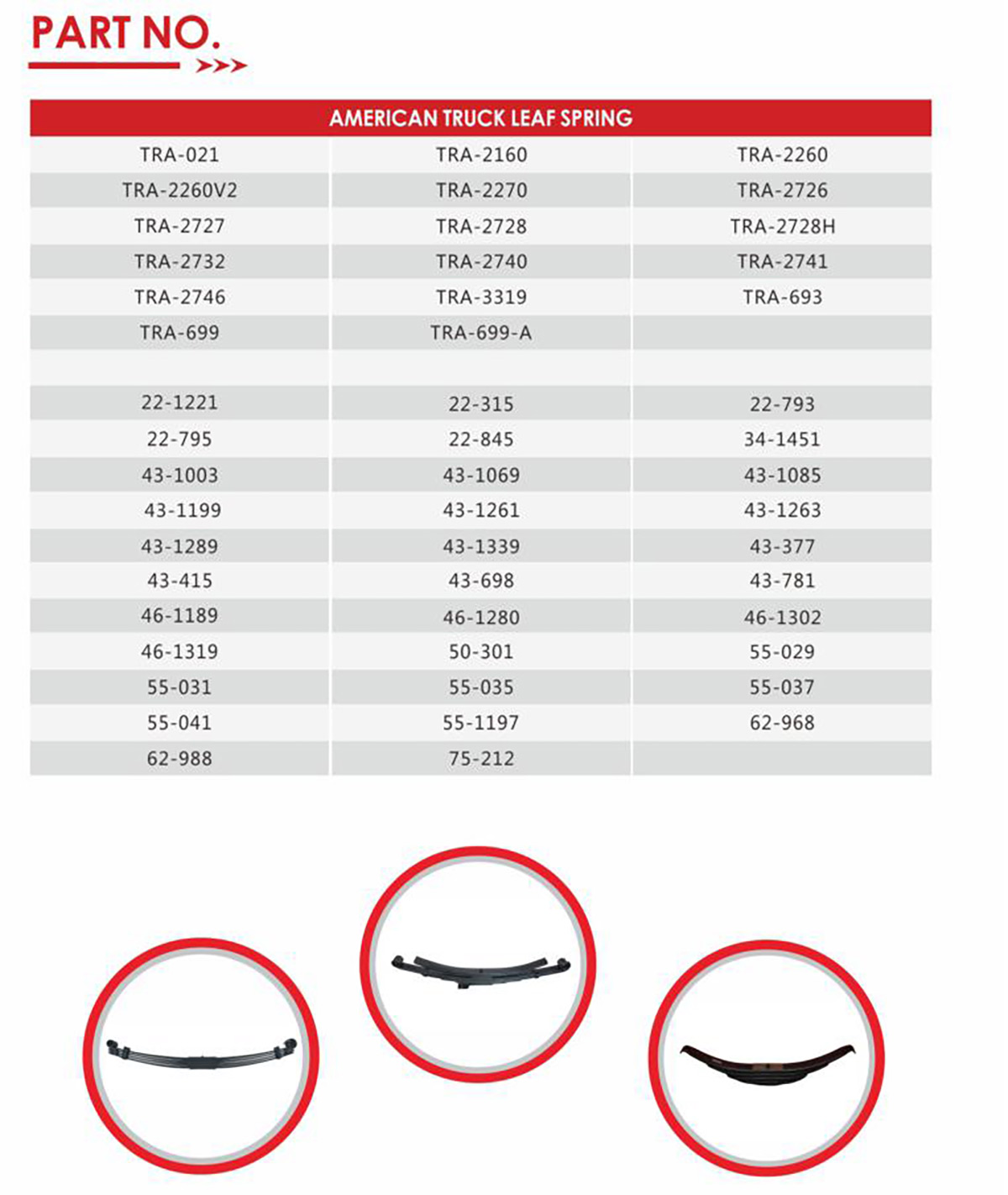

Leaf Spring Catalogue For American Market

Key Points Keep The High Quality

| 1) Raw matrail . |

| Thickness less than 20mm. we choose SUP9/55Cr3/SAE5160H as the product material |

| Thickness from 20-30mm. wE choose SUP11A/50CrVA |

| Thickness more than 30mm. We choose 51CrV4 as the raw material |

| Thickness more than 50mm. We choose 52CrMoV4 as the raw material |

| 2) Quchenging Process |

| We strickly controled the steel temeprure around 800 degree. |

| we swing the spring in the qenching oil among 10 seconds according to the spring thickness. |

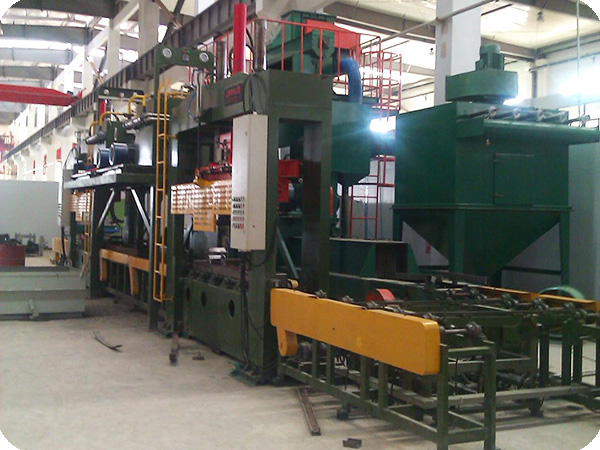

| 3)Shot Peening. |

| Each assmembing spring set under stress peening . |

| Fatigue test can reach over 150000 cycus |

| 4) Painting |

| Each leaf under cataphoresis painting. |

| Salt spray testing reach 500hours |

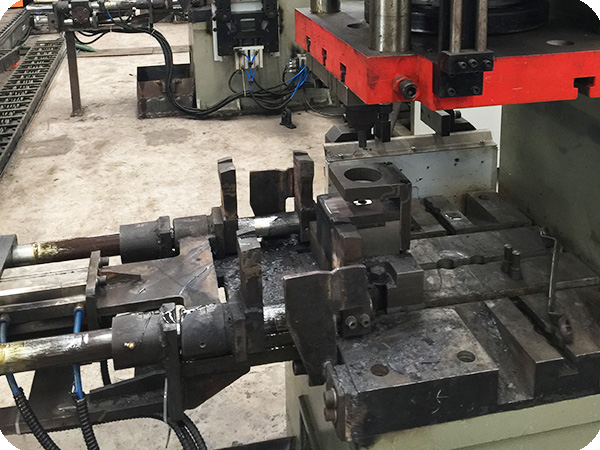

Production Process

1.Material Cutting

4.Edge Cutting

7.Stress Peening

2.Punching

5.Quenching

8.Assembling

3.Eye Rolling

6.Tempering

9.Painting

FAQ

Q1: What type of leaf spring could you produce ?

A: We can produce most kinds of springs in the market. especially on the parabolic springs.

Q2: What material could you supply for leaf spring?

A: Our material grade should be SUP9/SUP9A /SUP11A/51CrV4 /52CrMoV4/ even 55Cr3 and SAE5160H as well .

Q3: How long will be your delivery time?

A: 20-40days. If material stock enough around 20days. if not,would be 40days

Q4: What payment terms are acceptable?

A: TT and LC at sight

Q5: What is the packing?

A: No fumigation wooden pallet . we also can pack according to whatever you request if reasonable.

Q6:How about the surface finishing ?

A : electrophoresis coating (black,red,gray,or as customer’s requests )